How To Start a Tissue Converting Business In South America?

For newcomers who want to know more about tissue converting business and ask how to buy parent/jumbo rolls of tissue paper and convert them into toilet paper, napkins, and kitchen towel? This article will introduce it step by step for you!

1) Business model in one minute

- Buy tissue parent/jumbo rolls (base paper).

- Convert tissue base rolls into finished tissue products: toilet paper, napkins, kitchen towel, facial tissue, institutional jumbo bath rolls.

- Sell wholesale to distributors, cash & carry, HORECA (hotels, restaurants, cafés), institutions, and tenders.

Typical margin (indicative): 10–25% depending on scale, efficiency, and brand strength.

2) Starter budget (reference ranges in USD)

Ranges vary by country, exchange rate, freight, and whether you buy new or used machines. Use this as a starting point, not a quotation.

| Scale | Daily output (approx.) | What’s included | Estimated investment |

|---|---|---|---|

| Micro / pilot | 0.3–1 ton | Small rewinder, simple slitter, manual roll handling, basic bag/flow pack sealer, work table, air compressor | 30k–80k |

| Small | 1–3 tons | Semi-auto rewinder & slitter, basic emboss, semi-auto packer (bags), scale, compressor, used forklift | 80k–200k |

| Standard | 3–8 tons | Double-emboss rewinder, multi-slitter, automatic packing (flow pack/bags), strapping, shrink table, labeling | 200k–500k |

| Advanced | 8–20 tons | Fully automatic line, emboss/lamination, cartoning, palletizing, inline QC | 500k–1.2M+ |

Working capital (suggested minimum): 1–3 months of parent rolls, packaging (bags/film/cartons), labor, utilities, transport, and basic marketing.

3) Quick market research (2–4 weeks)

- Local demand: monthly consumption of toilet paper and napkins by channel (cash & carry, wholesalers, HORECA, institutions).

- Competitors: leading vs. economy brands; shelf vs. wholesale price levels.

- Gaps/opportunities:

- Strong demand for 1–2-ply economy SKUs.

- Growth in kitchen towel (half-roll formats).

- Institutional jumbo bath rolls for public restrooms.

- Starter portfolio (recommended):

- Toilet paper economy 1–2 ply, 200–300 sheets/roll.

- Napkins 1–2 ply (30×30 cm or 33×33 cm).

- Kitchen towel 2 ply with good absorbency.

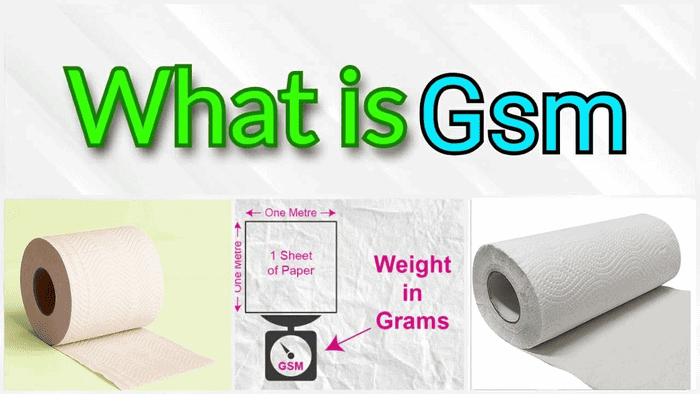

4) Product specifications that matter

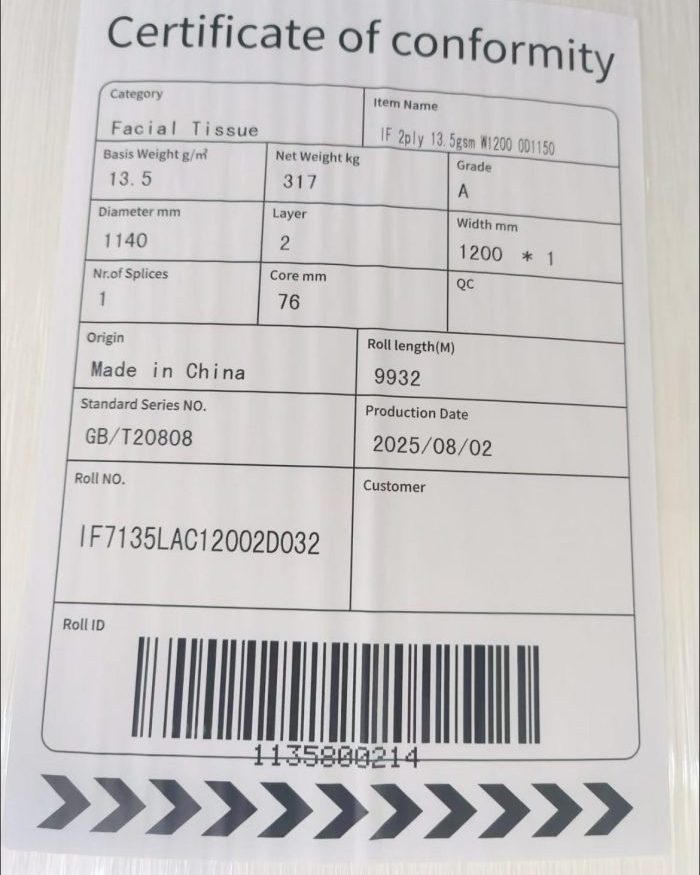

Tissue jumbo roll (base tissue):

- GSM ranges (typical):

- Toilet paper: 13–22 gsm

- Napkins tissue: 13–25 gsm

- Kitchen towel: 16–25 gsm

- Plies (layers): 1–2 (economy) or 3 (premium).

- Parent width: aligned to your finished roll cuts (e.g., 2000–2800 mm).

- Fiber: 100% virgin pulp, bamboo, or recycled blends (per positioning and local rules).

What end-users perceive:

- Softness, absorbency (towel), strength (wet/dry), and clean packaging with clear info.

5) Factory address selection (plant)

- Location: industrial park or warehouse with easy access to main road and port (if importing).

- Space needs:

- Micro: 200–500 m²

- Small/Standard: 600–2000 m²

- Utilities: three-phase power, ventilation, water, drainage, basic security.

- Material flow: receiving → conversion → packing → palletizing → dispatch.

- Permits: municipal/state license, health/environment (noise, paper dust, waste).

6) Minimum machinery to start

| Process | Equipment | Purpose |

|---|---|---|

| Rewinding & emboss | Rewinder with emboss (optional at start) | Makes the “finished log” with pattern; improves softness/bulk |

| Slitting | Multi-slitter | Defines roll width/length |

| Packing | Bag/flow-pack sealer/packer | Product protection and presentation |

| Support | Air compressor, scale, hand pallet/jack or forklift, work tables | Plant operations |

Tip: Early on, prioritize supplier reliability (spares, remote support) over the absolute lowest machine price.

7) Labour Demand (lean setup)

- Production: 2–6 operators per shift (depends on automation).

- Quality: 1 tech (softness, absorbency, roll length checks).

- Warehouse/Logistics: 1–2 staff.

- Sales: 1 salesperson + WhatsApp/major accounts.

- Admin: 1 person (purchasing, payments, taxes).

- Shifts: start with 1; move to 2 when you run >70–80% of capacity.

8) Cost structure (rule-of-thumb)

- Base paper (parent roll): 55–70%

- Packaging (bags/cartons/film): 8–15%

- Labor: 8–12%

- Energy & maintenance: 5–8%

- Sales & logistics: 5–10%

Target: total waste ≤ 3–5% (good setups, quick changeovers).

9) Sourcing tissue parent rolls (import vs. local)

If importing (operational checklist):

- HS Codes (reference):

- Base tissue in rolls/sheets: HS 4803

- Finished goods (toilet paper, napkins, etc.): HS 4818

- Incoterms: FOB/CIF/CFR by route and risk preference.

- Docs: invoice, packing list, BL/AWB, COO (if applicable), certifications (e.g., FSC if requested).

- Duties & VAT: confirm with your customs broker (varies by country).

- Sanitary/labeling: content, unit count/length, lot, origin, responsible/importer.

Freight & lead-times (indicative):

- Asia → Pacific coast LATAM: ~20–35 days on water.

- Keep 30–60 days safety stock when possible.

10) Registration, compliance & labels (country-specific)

- Business/industrial registration.

- Sanitary authorization if required for skin-contact products.

- Labeling: product name, plies, length/sheets, nominal GSM, lot/date, country of origin, importer/responsible info.

- H&S in plant: PPE, extinguishers, signage, paper-dust handling, waste.

Pro tip: Ask your parent-roll supplier for datasheets and declarations to ease local compliance.

11) Go-to-market in 30–60 days

- Branding: one value brand (price) and one standard brand (nicer feel).

- Portfolio: 2–3 fast movers (economy toilet paper, 1–2-ply napkins, 2-ply kitchen towel).

- Packaging: clean, legible, simple promises (“soft,” “absorbent,” “lasts longer”).

- Channels: wholesalers, minimarkets, HORECA, B2B platforms, social + WhatsApp.

- Pricing: anchor on your costs and market levels; avoid pure price wars without differentiation.

12) Suggested timeline (Day 0–120)

- Days 0–15: market scan, financial plan, contact suppliers, freight quotes.

- Days 15–45: secure site (lease/buy), order machines and parent rolls, start permits.

- Days 45–90: install equipment, hire team, run first production & packing trials.

- Days 90–120: finish registrations/labels, start commercial runs, deliver to first wholesalers.

13) Newcomer’s operational checklist

Before buying:

- Define 3 SKUs with exact sizes and plies.

- Validate prices & sell-through with 5–10 outlets.

- Quote parent rolls (right GSM and width).

- Budget packaging (bags/cartons) and labels.

- Confirm power capacity and floor space.

During purchasing:

- Choose Incoterm and customs broker.

- Plan stock for 1–2 months.

- Secure critical spare parts for machines.

At launch:

- Train operators on safety & quality.

- Track waste weekly.

- Record actual roll length per lot and handle claims formally.

14) FAQs for first-timers

Can I start with toilet paper only?

Yes. It’s the fastest-moving SKU. Add napkins or kitchen towel once you stabilize waste and sales.

Private label vs. contract manufacturing?

Do both early on: cash flow from contract jobs while you build your own brand.

Virgin vs. recycled fibers?

Depends on positioning and rules. For economy segments, 1–2-ply and lower GSM work if packaging is clean and honest.

Do I need certifications?

Basic retail often doesn’t. Chains/institutions may request FSC or others. Ask key customers in advance.

15) What details info we need to quote forTissue jumbo reels?

Share:

- Target products (toilet paper/napkins/kitchen towel) and plies

- GSM per product

- Parent width / cutting plan

- Monthly demand (tons)

- Destination port (for CIF) or Incoterm preference

Call to action (add to the end):

Ready to proceed? For machinery recommendations or tissue mother roll quotations (FOB/CIF), contact our team via WhatsApp +86 133 7771 0519 or email [email protected]—we’ll align specs, widths, and logistics to your market.