What Are Benefits Of Glue-Free Lamination Embossing For Tissue Paper Production?

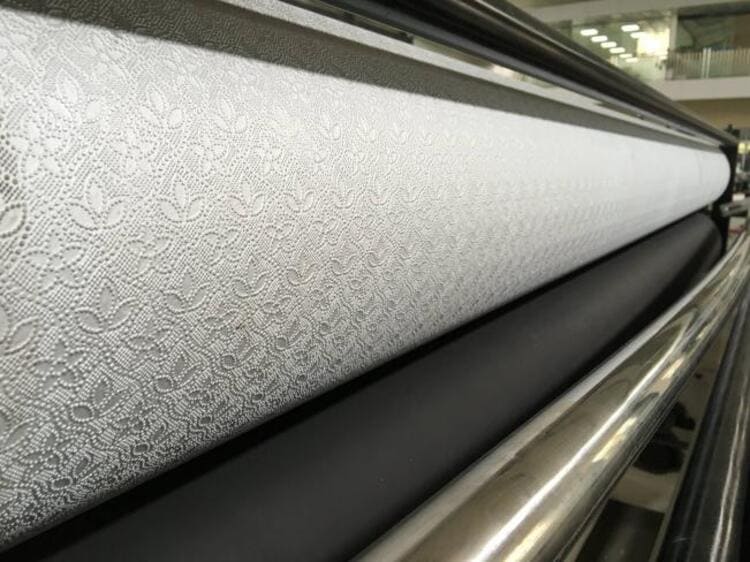

Tissue paper is a common household product that is used for various purposes, such as wiping, cleaning, and personal hygiene. Tissue paper is usually made of two or more layers of paper that are bonded together to create a thicker and stronger sheet. One of the methods to bond the layers of tissue paper is called lamination embossing, which involves creating raised patterns on the surface of the paper by pressing it between two rollers with different shapes. Lamination embossing can improve the quality and appearance of tissue paper, as well as its softness, absorbency, and strength.

However, traditional lamination embossing requires the use of glue or adhesives to attach the embossed layers together. This can have some drawbacks, such as increasing the production costs, energy consumption, and environmental impact of tissue paper manufacturing. Moreover, glue-based lamination embossing can limit the flexibility and customization of the embossing designs, as well as cause problems with the stability and durability of the embossed tissue paper.

To overcome these challenges, a new technology has emerged that allows lamination embossing without using any glue or adhesives. This technology is called glue-free lamination embossing, and it has many benefits for tissue paper production. In this article, we will explain what glue-free lamination embossing is, how it works, and why it is superior to traditional lamination embossing.

What is Glue-Free Lamination Embossing?

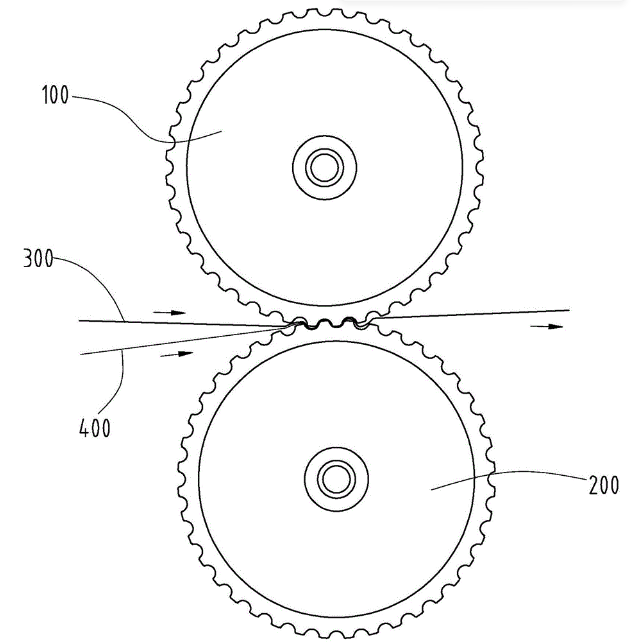

Glue-free lamination embossing is a process that bonds two or more plies of unembossed tissue paper together by applying heat, pressure, and nip forces in the regions where the plies are in contact with each other. The plies are passed through a press that consists of two rollers with male and female embossing patterns. The male roller has protruding shapes that fit into the recessed shapes of the female roller. The plies are pressed together between the rollers, creating raised patterns on both sides of the tissue paper. The heat and pressure activate the natural bonding properties of the fibers in the paper, making them stick together without any glue or adhesives.

How Does Glue-Free Lamination Embossing Work?

The key to glue-free lamination embossing is the use of unembossed plies that have not been previously treated with any chemicals or additives. Unembossed plies have more exposed fibers on their surfaces than embossed plies, which makes them more susceptible to bonding under heat and pressure. Moreover, unembossed plies have higher bulk and porosity than embossed plies, which means they can trap more air between them when they are pressed together. This creates a cushioning effect that enhances the softness and absorbency of the tissue paper.

The process of glue-free lamination embossing can be summarized as follows:

- Two unembossed plies are fed into a press with male and female embossing rollers

- The plies are aligned and synchronized so that they match each other in speed and position

- The plies are pressed together between the rollers at a temperature of about 150°C and a pressure of about 50 bar

- The heat and pressure activate the hydrogen bonds between the fibers in the paper, making them stick together in the regions where they are in contact

- The nip forces generated by the rollers also contribute to the bonding by compressing and deforming the fibers

- The plies exit the press as a single laminated sheet with embossed patterns on both sides

What Are The Benefits Of Glue-Free Lamination Embossing?

Glue-free lamination embossing has many advantages over traditional lamination embossing that uses glue or adhesives. Some of these advantages are:

- More environmentally friendly: Glue-free lamination embossing does not use any chemicals or additives that can harm the environment or human health. It also reduces waste generation and water consumption compared to glue-based processes.

- Reduces energy use and costs: Glue-free lamination embossing requires less energy than traditional lamination embossing because it does not need to apply, dry, or clean up any glue or adhesives. It also reduces maintenance costs and downtime due to fewer problems with equipment and product quality.

- Creates softer, more absorbent tissue paper: Glue-free lamination embossing produces tissue paper that has higher bulk, porosity, softness, and absorbency than glue-based products. This is because glue-free lamination embossing preserves more air between the plies and does not interfere with their natural properties.

- Allows more customization and flexibility in embossing designs: Glue-free lamination embossing enables more creativity and variety in creating embossing patterns on tissue paper. It allows for different combinations of shapes, sizes, depths, and densities of the patterns on both sides of the paper. It also allows for changing the embossing designs more easily and quickly than glue-based processes.

- Improves efficiency of production line: Glue-free lamination embossing simplifies and streamlines the production process of tissue paper by eliminating the need for glue application, drying, and cleanup. It also improves the stability and consistency of the product quality by avoiding issues with glue such as incomplete gluing, over-gluing, or under-gluing.

Why Is Glue-Free Lamination Embossing The Future For Tissue Paper Manufacturing?

Glue-free lamination 3D embossing is a revolutionary technology that offers many benefits for tissue paper production. It is more sustainable, economical, and efficient than traditional lamination embossing that uses glue or adhesives. It also creates tissue paper that is softer, more absorbent, and more attractive than glue-based products. Glue-free lamination embossing is the future for tissue paper manufacturing because it meets the needs and expectations of both producers and consumers in terms of quality, performance, and environmental impact. Glue-free lamination embossing is the best way to make tissue paper that is comfortable, reliable, and eco-friendly.

If you are looking for tissue paper parent reels for finished tissue production, Such as Toilet tissue, Facial tissue, hand towel, Kitchen towel and Napkins/ Serviettes, etc. Please feel free to contact us for any information. Click to Tel/ WhatsApp: +86 133 7774 0659