Why Does It Need to Add Dispersing Agent for Tissue Paper Production

Tissue paper is a staple item in households and businesses across the world. From facial tissues to toilet paper, its uses are diverse and essential in daily life. One critical aspect of tissue paper production is the inclusion of dispersing agents, which play a vital role in the overall quality and functionality of the finished product. This comprehensive guide will dive into the importance of dispersing agents in tissue paper production, discussing their functions, benefits, and the different types of agents used in the process. With over 5,000 words, this article will provide an in-depth look at why dispersing agents are crucial in tissue paper manufacturing.

The Role of Dispersing Agents in Tissue Paper Production

A. Overview of Dispersing Agents

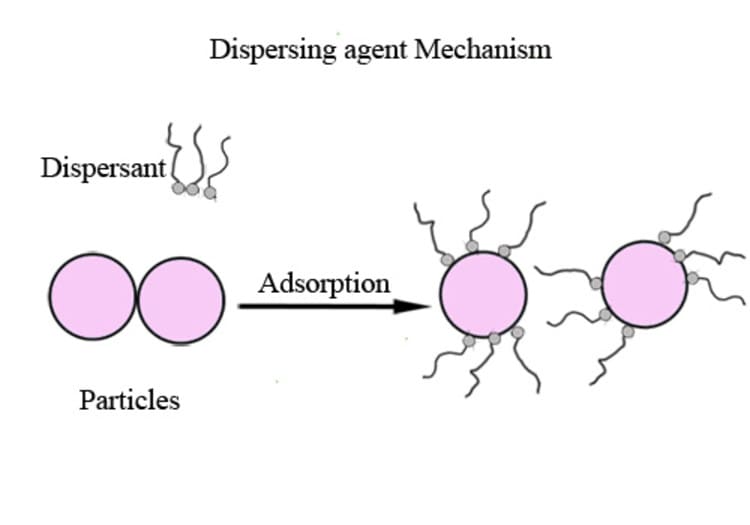

Dispersing agents, also known as dispersants, are chemicals used to improve the mixing of two or more incompatible substances. In tissue paper production, they aid in the dispersion of fibers, fillers, and other additives throughout the paper pulp, ensuring a consistent and uniform end product.

B. Importance of Proper Dispersion

Proper dispersion of materials in tissue paper manufacturing is essential to achieve certain prerequisites like consistent quality and optimal product appearance. The use of dispersing agents helps in achieving these prerequisites, which subsequently leads to enhanced product performance.

C. Mechanism of Dispersing Agents

Dispersing agents work by reducing the surface tension between particles in the pulp mixture, counteracting the natural tendency of these particles to stick together. This helps create a more homogeneous mixture, leading to improved physical characteristics in the tissue paper.

Benefits of Using Dispersing Agents in Tissue Paper Production

A. Improved Dry Strength and Softness

Dispersing agents contribute significantly to the dry strength of the tissue paper. By ensuring an even distribution of fibers and other components, they help create a network structure that imparts strength to the paper without compromising its softness.

B. Enhanced Wet Strength

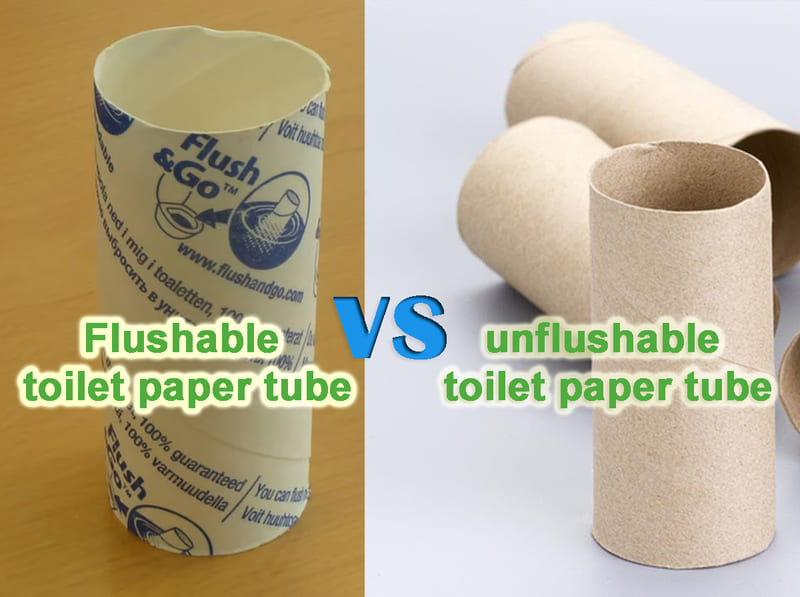

Wet strength is a vital property of tissue paper, especially for products like toilet paper and paper towels. Dispersing agents help improve wet strength by promoting effective fiber bonding, which leads to greater resistance to disintegration when wet.

C. Better Formation and Uniform Appearance

Proper dispersion of materials using dispersing agents leads to a more uniform formation of the paper web, resulting in even thickness, smoothness, and overall appearance. This is crucial for high-quality tissue paper, as it ensures consistent performance and an attractive, professional look.

D. Higher Pulp Yield and Cost Savings

The use of dispersing agents can lead to better utilization of raw materials. This translates to a higher pulp yield, meaning less wastage and lower production costs. In turn, these savings can be passed on to the customer, making tissue paper more affordable without compromising quality.

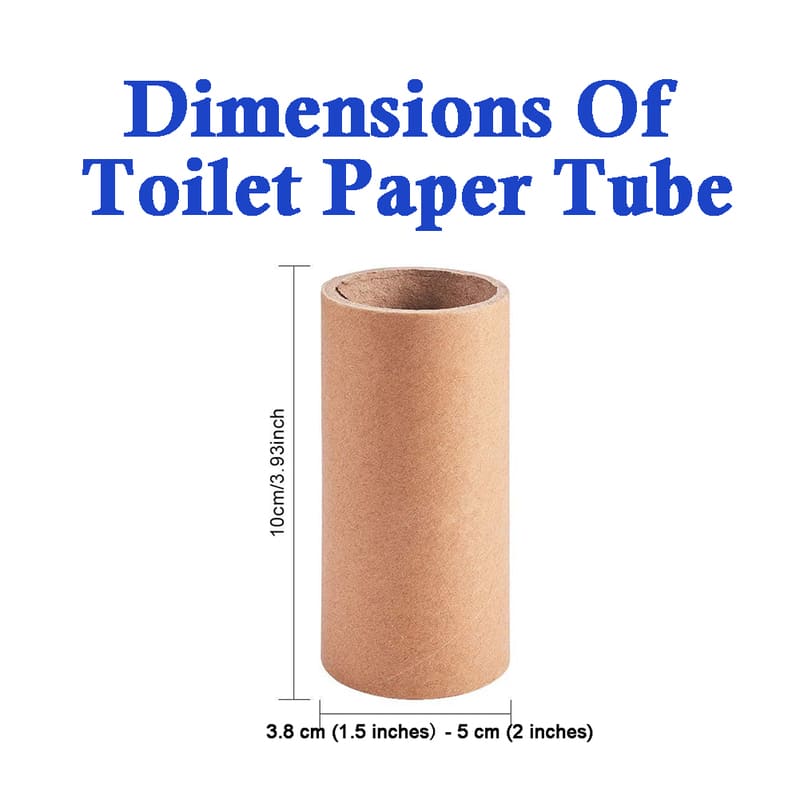

Indicators of Toilet Paper Quality

Different Types of Dispersing Agents Used in Tissue Paper Production

A. Inorganic Dispersing Agents

1. Sodium Hexametaphosphate (SHMP)

SHMP is a widely used inorganic dispersing agent that promotes the dispersion of fibers, fillers, and other materials within tissue paper pulp. Additionally, it helps to enhance the wet strength of the paper.

2. Sodium Tripolyphosphate (STPP)

STPP is another commonly used inorganic dispersing agent. It is particularly effective in dispersing calcium carbonate, a common filler used in tissue paper production.

B. Organic Dispersing Agents

1. Polyacrylates

Polyacrylates are a class of organic dispersing agents derived from acrylic acid. They offer excellent dispersion properties and are effective in enhancing the performance characteristics of tissue paper.

2. Polycarboxylates

Polycarboxylates, which include polycarboxylic acids and their salts, are another group of organic dispersants. They provide strong dispersion and stabilization effects, making them well-suited for tissue paper production.

Factors to Consider When Choosing a Dispersing Agent

A. Compatibility with Raw Materials and Production Process

It is crucial to select a dispersing agent that is compatible with the raw materials used in tissue paper production, as well as the specific manufacturing process. Incompatible agents can cause unwanted reactions or produce ineffective results.

B. Environmental and Health Impact

Dispersing agents can have varying environmental and health impacts. It is vital to choose a dispersing agent that complies with relevant regulations and is shown to have a minimal adverse effect on the environment and human health.

C. Cost-Effectiveness

A suitable dispersing agent should be cost-effective. This includes the cost of the agent itself and the potential cost savings in raw material usage and production process efficiency.

Conclusion

The inclusion of dispersing agents in tissue paper production is of paramount importance, as they contribute to the consistent quality, appearance, and strength of the end product. By understanding the specific functions and benefits of dispersing agents, tissue paper manufacturers can select the most appropriate agents for their product specifications and production processes. In doing so, they can ensure that their tissue paper products meet the high-performance standards expected by consumers while minimizing environmental impacts and production costs.

Related Topics

1. What is the Dispersing Agents for Tissue Paper Production

2. Understanding the Role of Dispersants in Tissue Paper Production

3. The Essential Function of Dispersing Agents in Tissue Paper Manufacturing

4. How Dispersing Agents Contribute to High-Quality Tissue Paper

5. Exploring the Use of Dispersing Agents for Efficient Tissue Paper Production