Do You Know How Embossing Print On Toilet Tissue?

Embossing is a process commonly used in the production of toilet paper and other tissue paper products. It involves pressing a pattern into the paper to create a raised relief design on the surface. Embossing not only makes the tissue softer and more absorbent, but also adds visual appeal. Here is an overview of the embossing process and its benefits for tissue manufacturers.

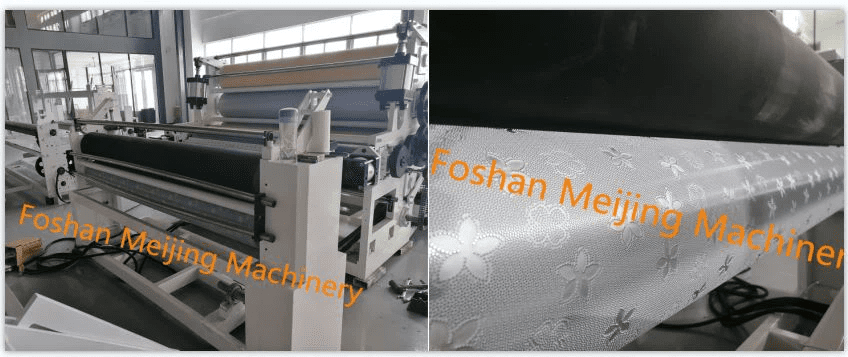

How Embossing Works

Embossing uses two rolls with complementary raised and recessed patterns to imprint designs onto paper. The paper is fed between the two rolls under high pressure, which presses the raised areas of one roll into the paper to create the embossed texture. Common embossing patterns include floral shapes, repeating geometric shapes, and abstract wavy lines.

Manufacturers use engraved metal rolls for embossing. The rolls can be engraved chemically or mechanically. Chemical etching uses acids to eat away parts of the roll surface not needing embossing. Mechanical engraving uses tools to directly cut or rout the design into the roll. The complexity of the pattern determines the engraving method.

Benefits of Embossing Toilet Paper

- Softness. Embossing makes tissue paper softer by creating more surface area. The raised bumps separate the paper fibers slightly, resulting in a fluffier, more absorbent sheet.

- Strength. Embossing compresses and fuses the paper fibers where they are pressed together, increasing the paper’s strength. This allows using fewer fibers to achieve the same wet strength.

- Aesthetics. Embossed shapes and textures make bath tissue more visually appealing to consumers. Eye-catching designs can aid product branding and differentiation.

- Absorbency. The separation of fibers creates more tiny pockets and channels to quickly absorb moisture. This helps toilet tissue feel drier against the skin.

- Differentiation. Varying emboss patterns and textures provides a way for manufacturers to distinguish their toilet paper lines.

Best Practices for Embossing

- Balance softness with strength by controlling embossing depth and paper weight. Deeper embossing increases softness but can compromise wet strength.

- Consider consumer preferences regarding embossed designs. Conduct market testing to determine appealing patterns.

- Use embossing to reinforce product brand identity through repeating logo shapes or motifs.

- Match embossing rolls to the paper furnish. Fine paper requires shallow embossing to prevent tearing.

With the right engraved rolls and process controls, embossing allows tissue manufacturers to optimize softness, strength, absorbency, branding, and product differentiation for toilet papers and other tissue products like Facial tissue, hand towel, Kitchen towel and Napkins etc.

YuanhuaPaper are a tissue paper mill with over 20 years in China.We supply tissue parent roll for toilet tissue, facial tissue, paper napkins and paper towel, etc.