How to Enhance Tissue Paper Softness with Softeners and Mechanical Treatments?

Tissue paper base paper is a lightweight paper or light crepe paper that is used for makingvarious tissue paper products, such as facial tissues, paper towels, napkins and bathroomtissue. Softness is an important quality attribute for tissue paper products, as it affects thecomfort, appearance and absorbency of the final product. The main objective of this article isto discuss how softeners and mechanical treatments can be used to enhance the softness oftissue paper base paper. The article will also compare and optimize the effects of thesemethods on tissue paper properties.

What are Softeners of tissue paper?

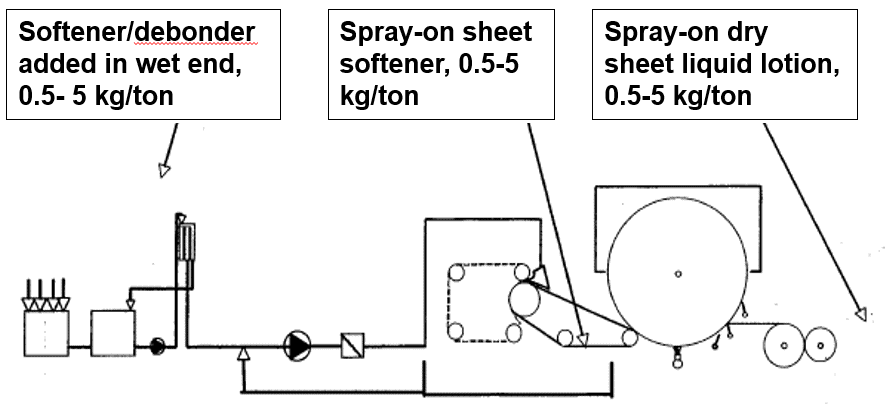

Softeners are chemical additives that are applied to the tissue paper base paper during orafter the production process. They can be classified into two main types: internal softenersand surface softeners. Internal softeners are added to the paper pulp before the dryingprocess, while surface softeners are sprayed or coated on the dried paper sheet. Thefunctions of softeners are to reduce the stiffness and friction of the paper fibers, increase thebulk and smoothness of the paper sheet, and improve the water retention and absorbency ofthe tissue paper product.

The benefits of using softeners for enhancing softness are:

- They can increase the softness of both virgin and recycled tissue paper base paper.

- They can improve the consumer perception and preference for tissue paper products.

- They can reduce the energy consumption and environmental impact of the tissue paperproduction process.

The drawbacks of using softeners for enhancing softness are:

- They can decrease the strength and durability of the tissue paper base paper.

- They can increase the cost and complexity of the tissue paper production process.

- They can cause health and safety issues if not used properly or excessively.

Some examples of softeners and their effects on tissue paper properties are shown in thetable below.

| Softener | Type | Effect on Softness | Effect on Other Properties |

| Quaternary ammonium compounds (QACs) | Internal | Increase | Decrease strength, increase absorbency |

| Polyethylene glycols (PEGs) | Internal | Increase | Decrease strength, increase absorbency |

| Polyvinyl alcohol (PVA) | Internal | Increase | Decrease strength, increase bulk |

| Silicone emulsions | Surface | Increase | Decrease strength, increase smoothness |

| Fatty acid esters | Surface | Increase | Decrease strength, increase smoothness |

| Lanolin derivatives | Surface | Increase | Decrease strength, increase water retention |

What are Mechanical treatments for tissue paper?

Mechanical treatments are physical processes that are applied to the tissue paper base paperduring or after the production process. They can be classified into two main types: crepingand embossing. Creping is a process that involves scraping the dried paper sheet off aheated cylinder with a blade, creating a crinkled surface with microfolds. Embossing is aprocess that involves pressing a patterned roller onto the dried paper sheet, creating a raisedsurface with microindentations. The functions of mechanical treatments are to increase thebulk and flexibility of the paper sheet, reduce the stiffness and density of the paper fibers,and enhance the visual appeal and texture of the tissue paper product.

The benefits of using mechanical treatments for enhancing softness are:

- They can increase the softness of both virgin and recycled tissue paper base paper.

- They can improve the consumer perception and preference for tissue paper products.

- They can create unique and distinctive designs and features for tissue paper products.

The drawbacks of using mechanical treatments for enhancing softness are:

- They can decrease the strength and durability of the tissue paper base paper.

- They can increase the energy consumption and environmental impact of the tissuepaper production process.

- They can cause quality variations and defects if not controlled properly or consistently.

Some examples of mechanical treatments and their effects on tissue paper properties areshown in the table below.

| Mechanical Treatment | Type | Effect on Softness | Effect on Other Properties |

| Creping with high adhesive strength | Creping | Increase | Decrease strength, increase bulk |

| Creping with low adhesive strength | Creping | Increase | Decrease strength, increase flexibility |

| Embossing with high pressure | Embossing | Increase | Decrease strength, increase bulk |

| Embossing with low pressure | Embossing | Increase | Decrease strength, increase flexibility |

Comparison and optimization

What is the Comparison and optimization of softeners and mechanical treatments for increase the softness of tissue paper?

Comparison and optimization

The effects of softeners and mechanical treatments on tissue paper softness and otherproperties are not independent, but rather interrelated and interdependent. Therefore, it isimportant to compare and optimize the use of these methods for tissue paper base paper.

Some of the factors that need to be considered are:

- The type and quality of the paper pulp used for tissue paper base paper.

- The type and amount of softeners used for tissue paper base paper.

- The type and intensity of mechanical treatments used for tissue paper base paper.

- The interactions and synergies between softeners and mechanical treatments.

- The trade-offs and compromises between softness and other properties, such asstrength, absorbency, bulk, smoothness, etc…

- The consumer expectations and preferences for tissue paper products.

- The cost and efficiency of the tissue paper production process.

- The environmental and social impacts of the tissue paper production process.

Some of the guidelines and recommendations for optimizing the use of softeners andmechanical treatments for tissue paper base paper are:

- Use a combination of internal and surface softeners to achieve a balanced effect onsoftness and other properties.

- Use a combination of creping and embossing to achieve a balanced effect on softnessand other properties.

- Adjust the adhesive strength, blade geometry, speed difference, pressure and pattern ofcreping and embossing according to the desired softness level and product design.

- Use recycled paper pulp with high-quality virgin paper pulp to reduce the need forsofteners and mechanical treatments.

- Use softeners and mechanical treatments that are biodegradable, renewable, safe andefficient to reduce the environmental and social impacts of the tissue paper productionprocess.

This article has discussed how softeners and mechanical treatments can be used to enhancethe softness of tissue paper base paper. It has also compared and optimized the effects ofthese methods on tissue paper properties.

The main findings and implications of the article are:

- Softeners and mechanical treatments are effective methods for enhancing softness oftissue paper base paper, but they also have some drawbacks and limitations.

- Softeners and mechanical treatments have interrelated and interdependent effects ontissue paper properties, which require careful comparison and optimization.

- Softeners and mechanical treatments need to be tailored to the type and quality of thepaper pulp, the consumer expectations and preferences, the cost and efficiency of the production process, and the environmental and social impacts of the productionprocess.

The main limitations and challenges of using softeners and mechanical treatments for tissue paper base paper are:

- The trade-offs and compromises between softness and other properties, such asstrength, absorbency, bulk, smoothness, etc.

- The quality variations and defects caused by inconsistent or improper application ofsofteners and mechanical treatments.

- The health and safety issues caused by excessive or improper use of softeners.

- The energy consumption and environmental impact caused by intensive or inefficientuse of softeners and mechanical treatments.

The main directions for future research and development are:

- Developing new types of softeners that are more effective, efficient, safe andenvironmentally friendly.

- Developing new types of mechanical treatments that are more effective, efficient,versatile and consistent.

- Developing new ways of combining softeners and mechanical treatments to achievesynergistic effects on tissue paper properties.

- Developing new ways of measuring and evaluating tissue paper softness objectivelyand subjectively.