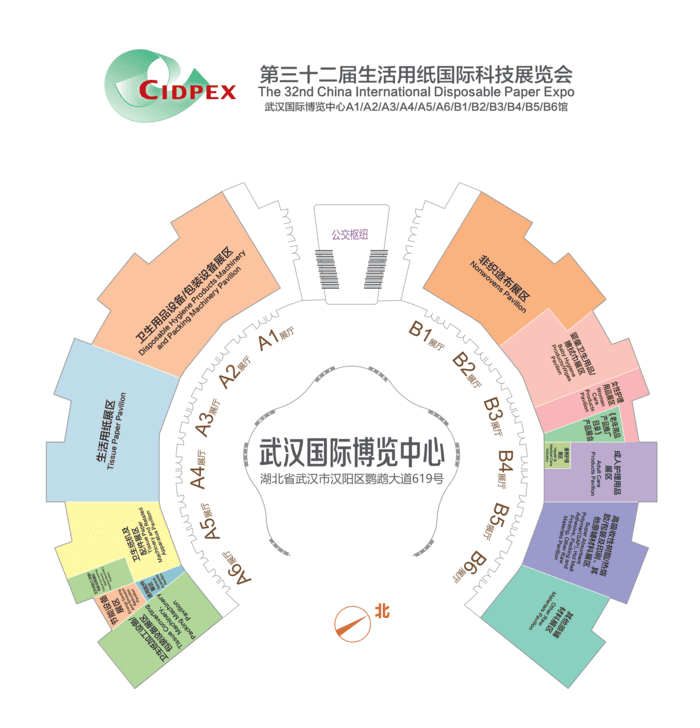

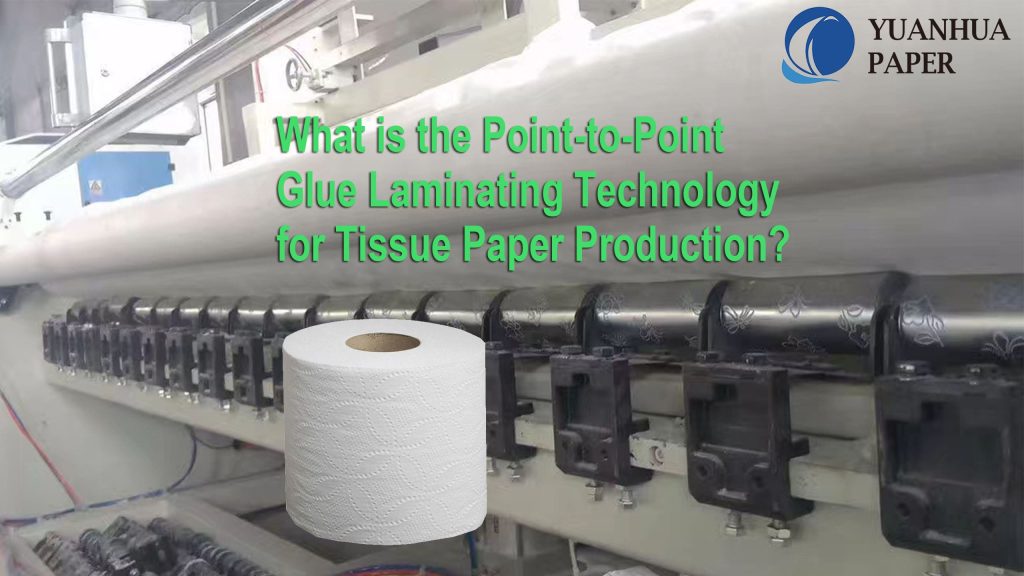

What is the Point-to-Point Glue Laminating Technology for Tissue Paper Production?

Tissue paper is a soft and absorbent paper product that people use for personal hygiene, cleaning, and wiping. Tissue paper can have one or more layers of paper, depending on how thick and strong it needs to be. One way to join multiple layers of tissue paper together is by using point-to-point (PTP) glue laminating technology.

How does PTP glue laminating technology work?

PTP glue laminating technology is a process that embosses and laminates two or more webs of tissue paper together by applying glue dots at specific points where the webs touch. The glue dots act as bonding agents that hold the webs together and create a three-dimensional structure that improves the bulk, softness, and absorbency of the tissue paper.

The process has the following steps:

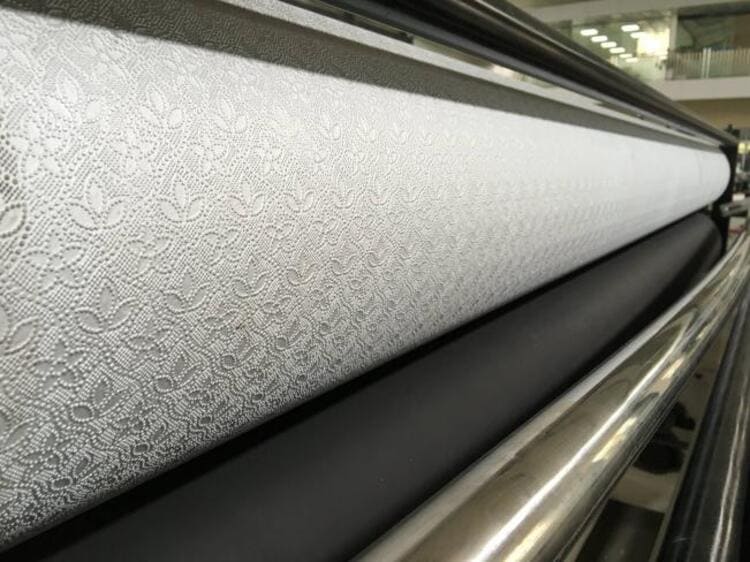

– The webs of tissue paper go into an embossing unit that has two or more steel rolls with engraved patterns on their surfaces. The patterns can be the same or different, depending on how the final product should look and feel.

– The embossing unit presses and heats the webs, creating raised areas (pegs) and recessed areas (valleys) on their surfaces. The pegs and valleys match the points where the glue dots will go later.

– The embossed webs then move to a laminating unit that has a glue applicator roll and a marrying roll. The glue applicator roll has small holes on its surface that put glue dots onto the pegs of one web. The marrying roll presses the other web onto the glued web, making sure the pegs and valleys line up in a point-to-point way. The glue dots stick the webs together at the contact points, forming a laminated tissue paper with a uniform thickness and a quilted look.

What are the pros and cons of PTP glue laminating technology?

PTP glue laminating technology has some pros and cons compared to other methods of making tissue paper, such as nested embossing technology or through-air drying technology.

Some of the pros are:

– PTP glue laminating technology can make tissue paper with high bulk, softness, absorbency, strength, and durability. The three-dimensional structure made by the glue dots gives cushioning and loft to the tissue paper, while also increasing its surface area and capillarity for better liquid absorption.

– PTP glue laminating technology can also make tissue paper with various designs and patterns, depending on the choice of embossing rolls and glue applicator rolls. The designs and patterns can make the tissue paper more attractive and functional, such as creating different textures, colors, or perforations.

– PTP glue laminating technology can also save energy and reduce environmental impact in making tissue paper, as it does not need to dry or rewet the webs after embossing. It also uses very little glue, as only small dots are applied at specific points.

Some of the cons are:

– PTP glue laminating technology can also cause some quality problems in making tissue paper, such as unevenness, delamination, or picking. Unevenness means variations in thickness or density across the tissue paper, which can affect how it performs and looks. Delamination means separation of the webs at the glue dots, which can lower the strength and integrity of the tissue paper. Picking means removal of fibers or adhesive from the tissue paper during use or processing, which can cause defects or contamination.

– PTP glue laminating technology also needs more complex and precise machines and operations than other methods of making tissue paper. The embossing rolls and glue applicator rolls have to be synchronized and aligned perfectly to ensure correct point-to-point contact between the webs. The temperature and pressure of the embossing unit have to be controlled carefully to avoid damaging or scorching the webs. The viscosity and amount of glue have to be adjusted according to the type and quality of tissue paper being made.

Conclusion

PTP glue laminating technology is a process that embosses and laminates two or more webs of tissue paper together by applying glue dots at specific points where the webs touch. It can make tissue paper with high bulk, softness, absorbency, strength, durability, design, and pattern. However, it can also create some quality problems such as unevenness, delamination, or picking. It also requires more complex and precise machines and operations than other methods of making tissue paper.

This blog post has given an overview of PTP glue laminating technology for tissue paper production, including what it is, how it works, and what are its pros and cons. For more information, please refer to the following sources:

: Tissue Embossing Developments | The Tissue Story

: Adhesive Solutions for Paper Converting Production – APPLIED Adhesives

: Lamination Techniques for Converters of Laminating Adhesives