The Industrial Use of Cellulose Fibers in Tissue Paper Industry

Tissue paper is a common household and personal hygiene product that is used for various purposes such as wiping, cleaning, and wrapping. The tissue paper industry is a large and growing sector that produces billions of tons of tissue paper every year. The quality and performance of tissue paper depend largely on the raw materials and the production process. One of the most important raw materials for tissue paper production is cellulose fibers, which are natural polymers derived from plants. Cellulose fibers have been used in paper production for centuries, but their role and potential in the tissue paper industry are still evolving. This article aims to explore the industrial use of cellulose fibers in the tissue paper industry, highlighting their advantages, challenges, and innovations.

Cellulose fibers are long chains of glucose molecules that form the structural component of plant cell walls. Cellulose fibers can be obtained from various sources such as wood, cotton, hemp, bamboo, and agricultural residues. The chemical structure and properties of cellulose fibers make them suitable for paper production, as they have high tensile strength, flexibility, hydrophilicity, and biodegradability. Cellulose fibers have been used in paper production since ancient times, as they can be easily processed into pulp by mechanical or chemical methods. The pulp can then be formed into sheets of paper by pressing and drying.

Cellulose fibers have several advantages in the tissue paper industry, as they can enhance the quality and functionality of tissue paper products. Some of the advantages are:

- Enhancement of tissue paper strength: Cellulose fibers can increase the strength of tissue paper by forming strong inter-fiber bonds through hydrogen bonding and entanglement. This can improve the durability and resistance of tissue paper to tearing, stretching, and wetting.

- Improvement in softness and absorbency: Cellulose fibers can also improve the softness and absorbency of tissue paper by creating a porous and fluffy structure that allows air and water to penetrate. This can enhance the comfort and performance of tissue paper for wiping and cleaning purposes.

- Sustainability and biodegradability aspects: Cellulose fibers are renewable and biodegradable resources that can reduce the environmental impact of tissue paper production and consumption. Cellulose fibers can be sourced from sustainable plantations or recycled from waste streams, reducing the need for deforestation and land use change. Cellulose fibers can also be easily decomposed by microorganisms or composted, reducing the waste generation and greenhouse gas emissions.

The process of incorporating cellulose fibers in tissue paper production involves several steps, such as harvesting, processing, conversion, integration, and quality control. The steps are:

- Harvesting and processing of cellulose fibers: Cellulose fibers are harvested from various plant sources using mechanical or manual methods. The harvested fibers are then cleaned, sorted, and dried to remove impurities and moisture.

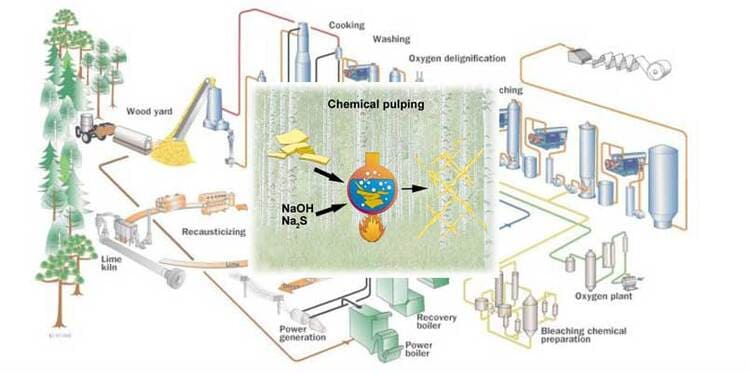

- Conversion of cellulose fibers into pulp: Cellulose fibers are converted into pulp by mechanical or chemical methods. Mechanical methods involve grinding or refining the fibers to break them down into smaller units. Chemical methods involve treating the fibers with chemicals such as sodium hydroxide or sulfuric acid to dissolve the lignin and hemicellulose components that bind the cellulose fibers together.

- Integration of the pulp into tissue paper manufacturing: The pulp is mixed with water and additives such as starch, dyes, fragrances, softeners, and wet strength agents to form a slurry. The slurry is then fed into a machine called a tissue machine that consists of four main sections: forming section, pressing section, drying section, and winding section. In the forming section, the slurry is spread over a moving wire mesh that drains the water and forms a thin layer of wet web. In the pressing section, the wet web is pressed between two rollers to remove more water and increase the density. In the drying section, the web is dried by hot air or steam to achieve the desired moisture content. In the winding section, the web is wound into large rolls called parent rolls that are later cut into smaller rolls or sheets for packaging.

- Quality control and testing of the final product: The final product is subjected to various quality control and testing procedures to ensure that it meets the specifications and standards for tissue paper products. Some of the quality parameters that are measured include basis weight, thickness, density, moisture content, tensile strength, tear resistance, burst strength, softness, absorbency, brightness, color, odor, etc.

The use of cellulose fibers in tissue paper production requires advanced machinery and techniques that can optimize the efficiency and effectiveness of the process. Some of the industrial techniques and innovations that are used or being developed are:

- Advanced machinery used for cellulose fiber processing: Some examples of advanced machinery used for cellulose fiber processing include twin-screw extruders, high-consistency refiners, high-pressure homogenizers, and microfluidizers. These machines can improve the quality and uniformity of the pulp by enhancing the fibrillation, dispersion, and modification of the cellulose fibers.

- Innovations in the use of cellulose fibers in tissue paper production: Some examples of innovations in the use of cellulose fibers in tissue paper production include nanocellulose, lyocell, and bacterial cellulose. Nanocellulose is a form of cellulose that has nanoscale dimensions and unique properties such as high surface area, high aspect ratio, high strength, and high biocompatibility. Nanocellulose can be used to improve the strength, softness, and functionality of tissue paper products. Lyocell is a form of cellulose that is produced by dissolving wood pulp in a solvent called N-methylmorpholine N-oxide (NMMO) and then spinning it into fibers. Lyocell has advantages such as high purity, high strength, high absorbency, and low environmental impact. Lyocell can be used to produce tissue paper products that are soft, smooth, and eco-friendly. Bacterial cellulose is a form of cellulose that is produced by certain bacteria such as Acetobacter xylinum that secrete cellulose as a by-product of their metabolism. Bacterial cellulose has advantages such as high purity, high crystallinity, high water retention, and high biocompatibility. Bacterial cellulose can be used to produce tissue paper products that are strong, flexible, and biodegradable.

- Potential future developments in cellulose technology in the tissue industry: Some examples of potential future developments in cellulose technology in the tissue industry include smart tissue paper, functional tissue paper, and 3D-printed tissue paper. Smart tissue paper is a type of tissue paper that can sense and respond to external stimuli such as temperature, pH, moisture, pressure, etc. Smart tissue paper can be used to create tissue paper products that have applications in health care, hygiene, and diagnostics. Functional tissue paper is a type of tissue paper that can perform specific functions such as antibacterial, antiviral, anti-inflammatory, antioxidant, etc. Functional tissue paper can be used to create tissue paper products that have applications in wound healing, infection prevention, skin care, etc. 3D-printed tissue paper is a type of tissue paper that can be printed into complex shapes and structures using 3D printing technology. 3D-printed tissue paper can be used to create tissue paper products that have applications in art, design, and engineering.

The use of cellulose fibers in tissue paper industry also faces some challenges that need to be addressed and overcome. Some of the challenges are:

- Economic considerations: The use of cellulose fibers in tissue paper production involves high costs for raw materials, processing equipment, energy consumption, and waste management. The cost of cellulose fibers may vary depending on the source, availability, quality, and demand of the fibers. The cost of processing equipment may depend on the type, capacity, efficiency, and maintenance of the equipment. The cost of energy consumption may depend on the amount and type of energy required for the various stages of production. The cost of waste management may depend on the amount and type of waste generated and the methods used for disposal or recycling.

- Environmental impact of cellulose fiber harvesting and processing: The use of cellulose fibers in tissue paper production also has an environmental impact that needs to be minimized and mitigated. The environmental impact may include deforestation, land degradation, biodiversity loss, water pollution, air pollution, greenhouse gas emissions, etc. The environmental impact may vary depending on the source, method, and scale of harvesting and processing of the cellulose fibers. The environmental impact can be reduced by adopting sustainable practices such as using renewable or recycled sources of cellulose fibers; using eco-friendly methods of harvesting and processing; using less water and chemicals; using cleaner energy sources; reducing waste generation; and implementing waste management strategies.

- Technical challenges in production and quality control: The use of cellulose fibers in tissue paper production also poses some technical challenges that need to be solved and improved. The technical challenges may include achieving optimal fiber properties; achieving optimal pulp quality; achieving optimal tissue paper quality; achieving optimal production efficiency; achieving optimal product performance; achieving optimal product safety; etc. The technical challenges may vary depending on the type, source, and quality of the cellulose fibers; the type, method, and conditions of pulp production; the type, method, and conditions of tissue paper production; the type, specifications, and standards of tissue paper products; the type, methods, and parameters of quality control; etc. The technical challenges can be overcome by using advanced machinery and techniques; using innovative materials and additives; using rigorous testing and evaluation methods; using feedback and improvement mechanisms; etc.

The use of cellulose fibers in tissue paper industry has been demonstrated by various case studies that show the successful industrial applications and outcomes of this technology. Some examples of case studies are:

- Case study 1: A Swedish company called Essity has developed a tissue paper product called Tork PeakServe that uses cellulose fibers from wheat straw, a by-product of cereal production. The product is designed to provide high capacity, high quality, and high sustainability for public washrooms. The product has advantages such as reducing water consumption by 60%, reducing energy consumption by 40%, reducing carbon footprint by 40%, and reducing land use by 33% compared to conventional tissue paper products.

- Case study 2: A Chinese company called C&S Paper has developed a tissue paper product called Bamboo Tissue that uses cellulose fibers from bamboo, a fast-growing and renewable plant. The product is designed to provide softness, strength, and eco-friendliness for household and personal use. The product has advantages such as saving 30% of wood pulp, saving 50% of water, saving 70% of bleaching chemicals, and saving 80% of carbon emissions compared to conventional tissue paper products.

- Case study 3: A Canadian company called Kruger Products has developed a tissue paper product called Cashmere EnviroCare that uses cellulose fibers from recycled paper, a waste stream from various sources. The product is designed to provide premium quality and environmental responsibility for consumers and businesses. The product has advantages such as diverting 100% of post-consumer paper from landfills, saving 60% of energy, saving 80% of water, and saving 100% of trees compared to conventional tissue paper products.

In conclusion, cellulose fibers are an essential and versatile raw material for the tissue paper industry, as they can improve the quality and functionality of tissue paper products while reducing the environmental impact of production and consumption. The use of cellulose fibers in tissue paper production involves various processes, techniques, and innovations that can optimize the efficiency and effectiveness of the technology. The use of cellulose fibers in tissue paper industry also faces some challenges that need to be addressed and overcome. The use of cellulose fibers in tissue paper industry has been demonstrated by various case studies that show the successful industrial applications and outcomes of this technology. The use of cellulose fibers in tissue paper industry has a significant potential for future development and growth, as it can create new opportunities and benefits for the industry and the society.