How Tissue Parent Reel Dimensions Affect the Hygiene Paper Industry

Tissue parent reels are large rolls of tissue paper that paper machines produce and then convert into various tissue products, such as toilet paper, facial tissue, napkins, and paper towels. Tissue parent reels are essential for the hygiene paper industry because they determine the quality, quantity, and efficiency of the final products.

The dimensions of tissue parent reels affect the production process, storage capacity, transportation costs, and end-user satisfaction. Therefore, both manufacturers and buyers need to understand the dimensions of tissue parent rolls. This guide explains the dimensions of tissue parent reels and how they affect the tissue reels sector.

What are the Dimensions of Tissue Parent Reels?

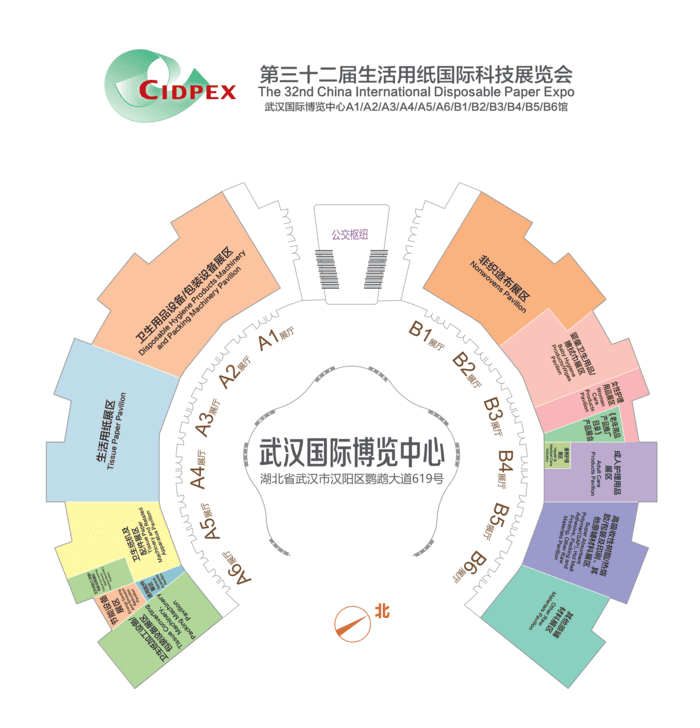

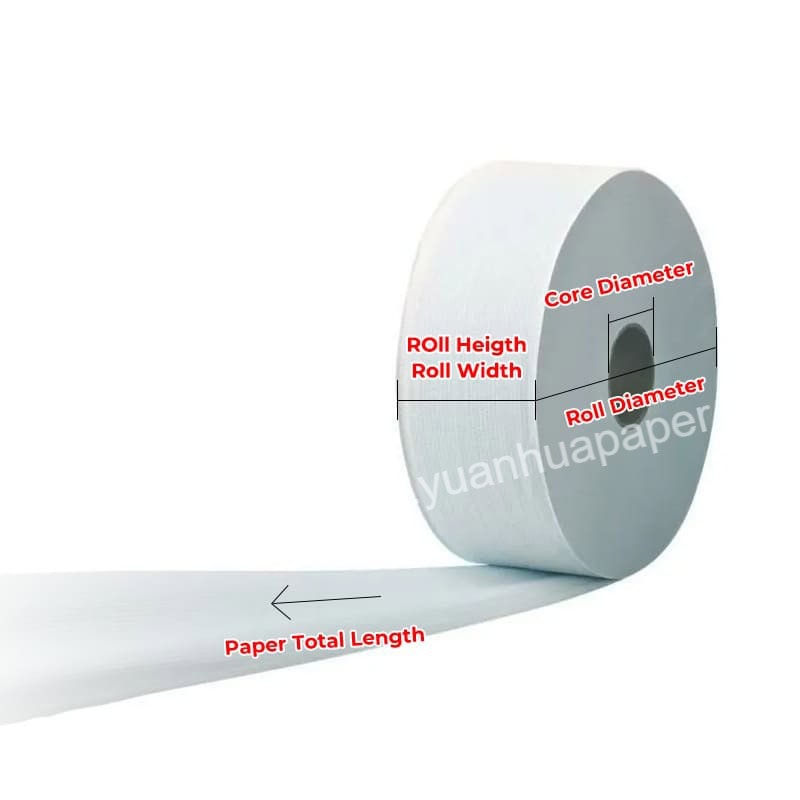

The dimensions of tissue parent reel consist of four main elements: core diameter, roll diameter, roll width/height, and paper length. Each element has a significant impact on the performance and profitability of tissue reels.

- Core diameter: The core diameter is the inner diameter of the cardboard tube that supports the tissue paper. It determines the stability and strength of the tissue parent roll and its compatibility with the paper machine and the converting equipment.

- Roll diameter: The roll diameter is the outer diameter of the tissue parent reel, measured from one edge to the other. It affects the production speed, the storage space, and the transportation efficiency of the tissue parent reel.

- Roll width/height: The roll width or height is the dimension of the tissue parent reel perpendicular to the roll diameter, measured from the core to the edge. It determines the number of tissue products that can be produced from a single tissue paper parent reel and the quality and consistency of the tissue paper.

- Paper length: The paper length is the total length of the tissue paper wound around the core. It depends on the thickness and the density of the tissue paper and the roll diameter and the roll width or height. It influences the production capacity, the product variety, and the end-user convenience of the tissue paper parent roll.

These dimensions of tissue paper reels are interrelated and need to be carefully balanced to achieve optimal results. The following sections explore each dimension in more detail and provide some examples and case studies to illustrate their importance.

Why Core Diameter Matters

The core diameter is the foundation of the tissue parent reel because it supports the weight and the tension of the tissue paper. The core diameter needs to be strong enough to withstand the pressure and the friction of the paper machine and the converting equipment and to prevent the tissue paper from collapsing or tearing.

The standard core diameters for tissue parent reels are 3 inches (76 mm), 6 inches (152 mm), and 12 inches (305 mm). However, some manufacturers and buyers may prefer custom sizes to suit their specific needs. The choice of core diameter depends on several factors, such as:

The type and the size of the paper machine and the converting equipment. Different machines may require different core diameters to fit their specifications and to ensure smooth operation.

The roll diameter and the roll weight. Larger and heavier rolls may need larger core diameters to support them and to avoid deformation or damage.

The transportation and the storage conditions. Smaller core diameters may allow for more tissue paper to be wound around the core, reducing the transportation and the storage costs. However, smaller core diameters may also increase the risk of crushing or bending during handling or loading.

A real-life example of how core diameter can affect the tissue paper reel performance is the case of [ABC Paper], a leading tissue paper manufacturer in the US. ABC Paper used to produce tissue parent reels with a core diameter of 6 inches, but they faced some challenges with their customers, who complained about the difficulty of loading and unloading the reels and the waste of paper and space. ABC Paper switched to a core diameter of 3 inches, which resulted in a 20% increase in paper length, a 15% reduction in transportation and storage costs, and a 10% improvement in customer satisfaction.

How Roll Diameter Impacts Production and Transport?

The roll diameter is another key dimension of the tissue paper reel because it affects the production efficiency, the storage capacity, and the transportation costs. The roll diameter needs to be large enough to maximize the paper length and to reduce the number of reel changes, but not too large to cause problems with the machinery, the storage, and the shipping.

The standard roll diameters for tissue paper reels range from 40 inches (1016 mm) to 120 inches (3048 mm), depending on the type and the quality of the tissue paper. However, some manufacturers and buyers may opt for custom sizes to meet their specific requirements. The choice of roll diameter depends on several factors, such as:

- The type and the quality of the tissue paper. Different types and qualities of tissue paper may have different thicknesses and densities, which affect the roll diameter and the paper length. For example, softer and bulkier tissue paper may require smaller roll diameters to avoid crushing or wrinkling, while stronger and thinner tissue paper may allow for larger roll diameters to increase the paper length.

- The production speed and the frequency of reel changes. Larger roll diameters may enable faster production and fewer reel changes, saving time and labor costs. However, larger roll diameters may also increase the risk of paper breaks or defects, requiring more maintenance and quality control.

- The storage space and the transportation efficiency. Smaller roll diameters may save storage space and transportation costs, as they can fit more reels in a given area or container. However, smaller roll diameters may also reduce the paper length and increase the number of reels needed, resulting in more handling and loading costs.

A case study from a tissue paper manufacturer that illustrates the impact of roll diameter on their operations is the case of Metsä Tissue, a leading tissue paper producer in Europe. Metsä Tissue used to produce tissue parent reels with a roll diameter of 80 inches, but they faced some challenges with their customers, who demanded more variety and flexibility in their tissue products. Metsä Tissue switched to a roll diameter of 60 inches, which allowed them to produce more types and sizes of tissue products, such as toilet paper, facial tissue, and napkins, from the same tissue parent reel. This resulted in a 25% increase in product variety, a 20% increase in production flexibility, and a 15% increase in customer loyalty.

What Roll Width/Height Means for Production and Quality

The roll width or height is another important dimension of the tissue mother reel because it affects the production line and the end-product. The roll width or height determines the number of tissue products that can be produced from a single tissue parent reel and the quality and consistency of the tissue paper.

The standard roll widths or heights for tissue mother rolls vary from 40 inches (1016 mm) to 200 inches (5080 mm), depending on the type and the size of the tissue products. However, some manufacturers and buyers may choose custom sizes to suit their specific needs. The choice of roll width or height depends on several factors, such as:

The type and the size of the tissue products. Different types and sizes of tissue products may require different roll widths or heights to match their specifications and to ensure optimal quality. For example, toilet paper may need smaller roll widths or heights to fit the dispensers and to avoid wastage, while paper towels may need larger roll widths or heights to provide more absorbency and durability.

The production line and the converting equipment. Different production lines and converting equipment may require different roll widths or heights to fit their capabilities and to ensure smooth operation. For example, some production lines may have limitations on the maximum or minimum roll width or height they can handle, while some converting equipment may have preferences on the optimal roll width or height they can process.

The production efficiency and the waste reduction. Larger jumbo roll widths or heights may increase the production efficiency and reduce the waste, as they can produce more tissue products from a single tissue parent reel. However, larger roll widths or heights may also increase the risk of quality issues or defects, requiring more inspection and correction.

An example of how changing roll width or height can optimize production for a tissue paper company is the case of Asia Symbol (Guangdong) Paper, a leading tissue paper supplier in Asia. Asia Symbol (Guangdong) Paper used to produce tissue parent reels with a roll width of 100 inches, but they faced some challenges with their customers, who requested more customized and personalized tissue products. Asia Symbol (Guangdong) Paper switched to a roll width of 80 inches, which enabled them to produce more sizes and designs of tissue products, such as printed and embossed tissue paper, from the same tissue parent reel. This resulted in a 30% increase in product customization, a 20% increase in production efficiency, and a 10% reduction in waste.

How Paper Length Affects Production and Usage?

The paper length is the final dimension of the bobinas papel tissue, and it is determined by the thickness and the density of the tissue paper, as well as the roll diameter and the roll width or height. The paper length influences the production capacity, the product variety, and the end-user convenience of the tissue parent reel.

The standard paper lengths for tissue parent reels range from 10,000 feet (3048 m) to 50,000 feet (15,240 m), depending on the type and the quality of the tissue paper. However, some manufacturers and buyers may prefer custom lengths to meet their specific demands. The choice of paper length depends on several factors, such as:

- The type and the quality of the tissue paper. Different types and qualities of tissue paper may have different thicknesses and densities, which affect the paper length and the paper weight. For example, softer and bulkier tissue paper may have shorter paper lengths and lighter paper weights, while stronger and thinner tissue paper may have longer paper lengths and heavier paper weights.

- The production capacity and the product variety. Longer paper lengths may increase the production capacity and the product variety, as they can produce more tissue products from a single tissue parent reel. However, longer paper lengths may also increase the complexity and the variability of the production process, requiring more adjustments and controls.

- The end-user convenience and the product performance. Shorter paper lengths may improve the end-user convenience and the product performance, as they can provide more freshness and hygiene for the tissue products. However, shorter paper lengths may also increase the frequency of product replacement and the amount of packaging waste.

The dimension of tissue parent roll that relates to paper length is an important factor to consider for both manufacturers and buyers, as it affects the quality and the quantity of the tissue products. A case study that demonstrates the importance of paper length is the case of Must Paper Industries, a leading tissue paper distributor in Africa. Must Paper Industries used to source tissue parent reels with a paper length of 30,000 feet, but they faced some challenges with their customers, who complained about the poor quality and the high cost of the tissue products. Must Paper Industries sourced tissue parent reels with a paper length of 20,000 feet, which improved the quality and the affordability of the tissue products, as well as the customer satisfaction and loyalty.

How to Choose the Right Tissue Parent Roll Size

The tissue parent roll size is the result of the combination of the four dimensions discussed above: core diameter, roll diameter, roll width/height, and paper length. The tissue parent roll size determines the overall performance and profitability of the tissue jumbo reel, as well as the tissue products derived from it.

Choosing the right tissue parent roll size is a critical decision for both manufacturers and buyers, as it affects the production process, the storage capacity, the transportation costs, the product variety, the product quality, and the end-user satisfaction. The choice of tissue parent roll size depends on several factors, such as:

- The type and the quality of the tissue paper. Different types and qualities of tissue paper may have different specifications and requirements for the tissue parent roll size, as well as different preferences and expectations from the customers.

- The production line and the converting equipment. Different production lines and converting equipment may have different capabilities and limitations for the tissue parent roll size, as well as different efficiencies and costs associated with it.

- The market demand and the customer needs. Different market segments and customer groups may have different demands and needs for the tissue parent roll size, as well as different price sensitivities and value perceptions.

The tissue parent roll size is a key factor that influences the success and the competitiveness of the tissue reel sector. Therefore, it is essential to understand the dimensions of grande bobinas papel tissue and how they affect the tissue parent roll size, as well as to consider the various factors that influence the choice of tissue parent roll size.

Conclusion

Tissue parent reels are vital for the hygiene paper industry, as they are the raw material for the production of various tissue products like Toilet tissue, Facial tissue, hand towel, Kitchen towel and Napkins etc. Understanding the dimensions of tissue parent reels is crucial for both tissue manufacturers and buyers, as they affect the quality, quantity, and efficiency of the tissue products, as well as the tissue making process, the storage capacity, the transportation costs, and the end-user satisfaction.

As above mentioned, the dimensions of Jumbo Tissue Reels, including core diameter, roll diameter, roll width/height, and paper length, and how they impact the tissue parent roll size. It has also discussed the importance of choosing the right tissue parent roll size for specific needs and preferences, and the factors that influence this decision.

We hope that this article has helped you to gain a better understanding of the dimensions of tissue parent reels and how they affect the tissue reels sector. If you have any questions or inquiries, or if you want to view our products, please feel free to contact us. We are happy to assist you with your tissue manufacturing.

Related Topic:

- how long is a toilet paper roll tube in inches?

- how long is a toilet paper roll in cm?

- toilet roll dimensions cm?

- what is the height of a toilet paper roll?

- thickness of toilet paper in mm?