How are tissue paper manufacturing by tissue paper converting machine?

Tissue paper is a soft, absorbent, and disposable paper product that is widely used for personal hygiene, cleaning, and medical purposes. Tissue paper products include facial tissues, toilet paper, paper towels, paper napkins, and medical-grade tissue products. But how are these products manufactured by tissue paper converting machines? In this article, we will explain the process of tissue paper production and converting, and the role of tissue paper converting machines in this industry.

Tissue paper production process

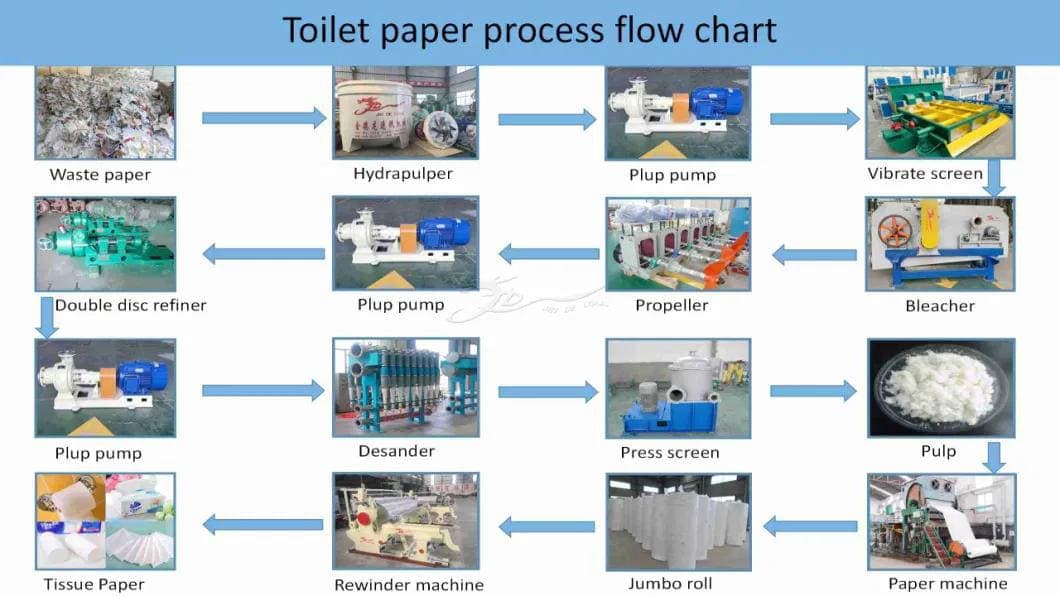

The first step in tissue paper production is to obtain the raw material, which is usually wood pulp or recycled paper. Wood pulp is obtained by chemically or mechanically pulping wood chips, which separates the cellulose fibers from the lignin and other impurities. Recycled paper is obtained by collecting and sorting waste paper, which is then de-inked, cleaned, and refined to remove any contaminants and produce pulp.

The pulp is then mixed with water and chemicals to form a slurry, which is fed into a paper machine. The paper machine consists of four main sections: the forming section, the press section, the drying section, and the creping section.

- The forming section is where the slurry is sprayed onto a rotating wire mesh, called the forming fabric, which drains the water and forms a thin layer of wet paper, called the web.

- The press section is where the web is pressed between two rollers, called the press rolls, which squeeze out more water and increase the strength and smoothness of the paper.

- The drying section is where the web is dried by passing through a series of heated cylinders, called the dryers, which evaporate the remaining water and increase the softness and bulk of the paper.

- The creping section is where the web is scraped off the last dryer by a sharp blade, called the creping blade, which creates small wrinkles and folds in the paper, called the crepes, which enhance the flexibility and absorbency of the paper.

The resulting paper is then wound onto a large roll, called the parent roll, which is ready for converting.

Tissue paper converting process

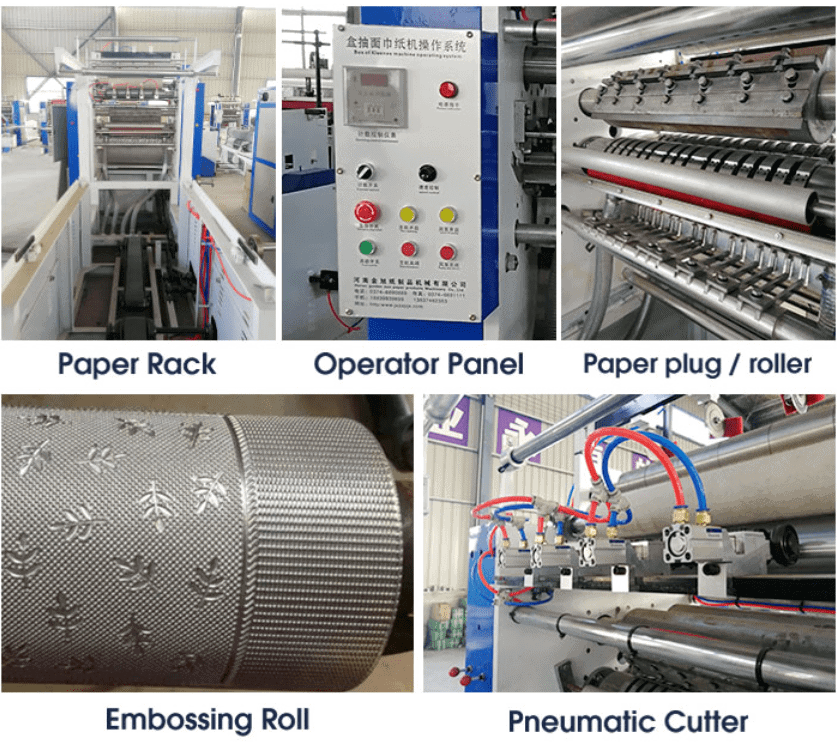

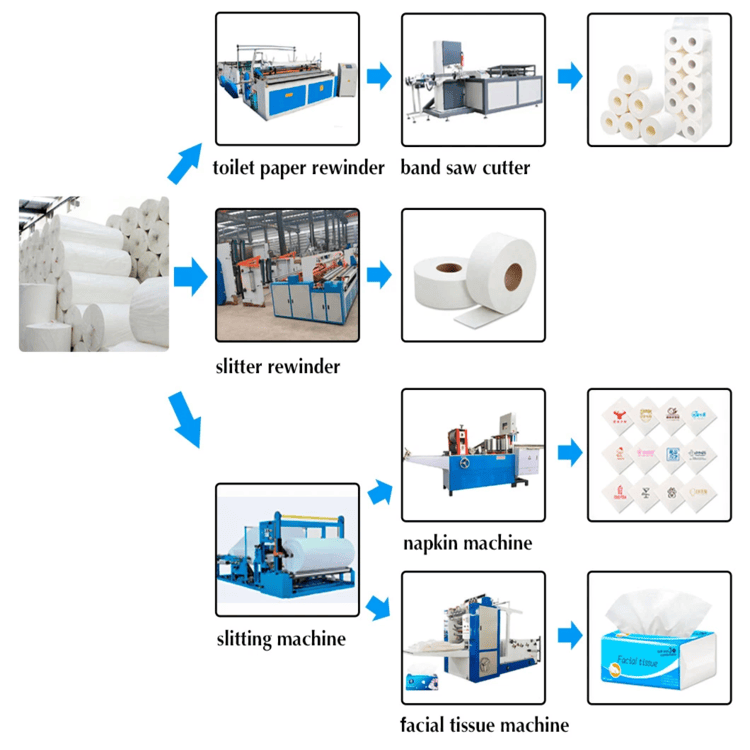

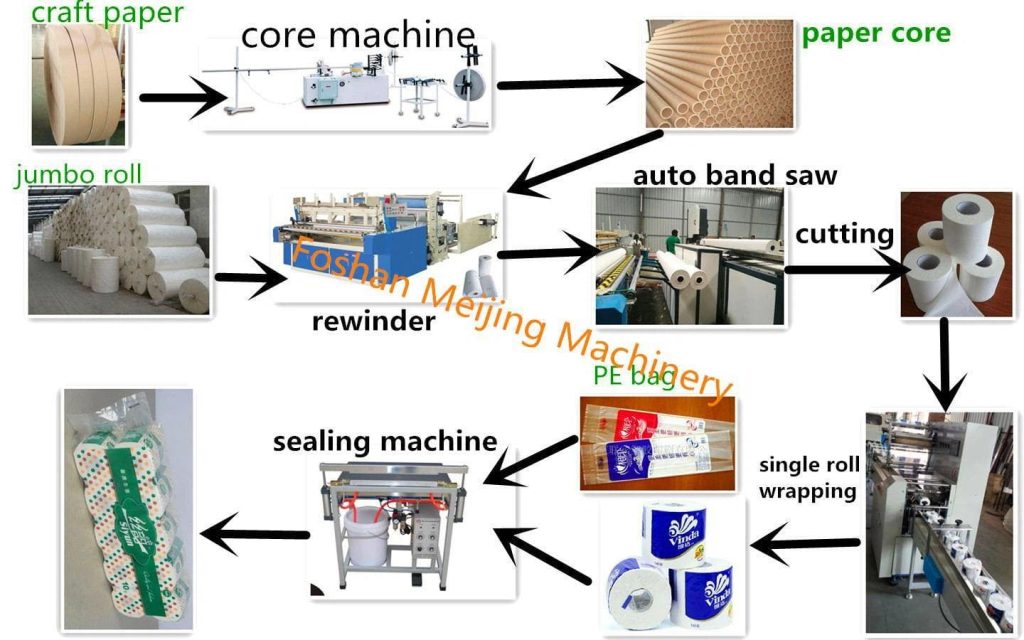

The second step in tissue paper production is to convert the parent roll into finished tissue paper products, such as facial tissues, toilet paper, paper towels, napkins, and medical-grade tissue products. This is done by tissue paper converting machines, which are specialized machines that perform various functions, such as cutting, embossing, laminating, printing, folding, perforating, and packaging.

The main types of tissue paper converting machines are:

- Toilet roll converting machines, which cut the parent roll into smaller rolls of toilet paper, and perforate them into individual sheets. Some machines also emboss the paper with patterns or logos, and package the rolls into plastic wrappers or cardboard boxes.

- Facial tissue converting machines, which cut the parent roll into smaller sheets of facial tissue, and fold them into rectangular or square shapes. Some machines also print the paper with colors or designs, and package the sheets into cardboard boxes or plastic bags.

- Paper towel converting machines, which cut the parent roll into smaller rolls of paper towel, and perforate them into individual sheets. Some machines also emboss or print the paper with patterns or logos, and package the rolls into plastic wrappers or cardboard boxes.

- Napkin converting machines, which cut the parent roll into smaller sheets of napkin, and fold them into various shapes, such as square, rectangular, or round. Some machines also emboss, print, or laminate the paper with colors or designs, and package the sheets into plastic bags or cardboard boxes.

- Medical-grade tissue converting machines, which cut the parent roll into smaller sheets of medical-grade tissue, and fold them into sterile shapes, such as gauze, bandage, or swab. Some machines also sterilize the paper with chemicals or radiation, and package the sheets into sealed pouches or containers.

Conclusion

Tissue paper is a versatile and essential product that is used for various purposes, such as personal hygiene, cleaning, and medical care. Tissue paper production and converting are complex and sophisticated processes that involve various machines and technologies. Tissue paper converting machines are the key machines that transform the parent roll into finished tissue paper products, such as facial tissues, toilet paper, paper towels, napkins, and medical-grade tissue products. Tissue paper converting machines are designed to perform various functions, such as cutting, embossing, laminating, printing, folding, perforating, and packaging, to meet the diverse needs and preferences of consumers and businesses.

People also ask?

- What machines are used to make tissue paper?

- What is the process of converting tissue paper?

- How do you manufacture tissue paper?

- What is paper converting machine?

- How is tissue paper manufactured?

- What is a tissue converter?