What’s The Measurement Unit “Gsm” For Tissue Paper?

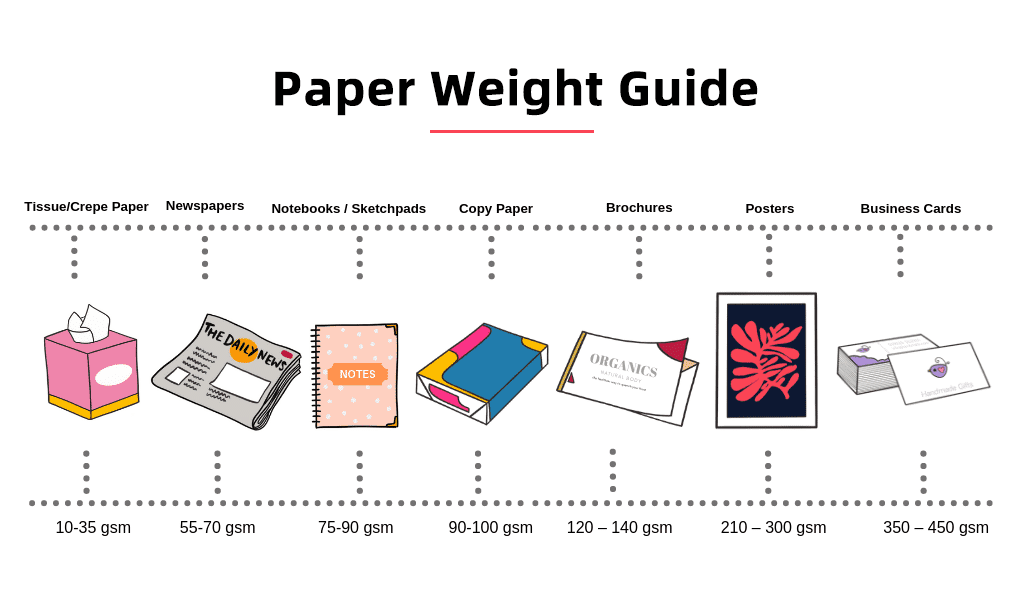

To appreciate the functionality of a product as commonplace as tissue paper, it is important to delve into the metrics that define its quality and utility. One such critical measurement unit in the paper industry is GSM, short for grams per square meter. It is a universal unit of measurement, acting as an essential scale for evaluating the physical properties of various paper types, including tissue paper.

What is GSM?

GSM is an acronym for Grams per Square Meter. This unit is employed to measure the weight and thereby the density of various types of paper and fabric materials. The concept is simple; the weight (in grams) of a square meter (1000 x 1000mm or 1m2) piece of the material gives the GSM value.

A higher GSM number implies a denser, thicker, and generally more substantial material. Conversely, a lower GSM indicates a lighter, thinner, and potentially less durable material. For tissue paper, GSM can directly correlate to its strength, softness, absorbency, and overall quality. And grams per square meter (gsm) gives a much better idea as to the actual thickness of a paper. As a general rule, anything 10-35 gsm is of tissue consistency.

The Role of GSM in Measuring Tissue Paper

As a universally applicable unit of measurement, GSM plays a pivotal role in evaluating and comparing tissue paper’s physical attributes.

1. Quality Indication:

The GSM of tissue paper is an essential measure of its quality. Higher GSM tissue papers tend to be thicker, more absorbent, and generally more durable, leading to a higher-quality product. Lower GSM tissue papers, while not necessarily of low quality, tend to be thinner, less absorbent, and may not hold up as well under use.

2. Determining Purpose:

The GSM of tissue paper also helps determine its best-suited purpose. For instance, tissue papers with a lower GSM are typically used for facial tissues or toilet paper, while those with a higher GSM are often used for paper towels and napkins. This is because the higher absorbency and durability of high GSM tissue papers make them better suited to tasks that require these qualities.

3. Cost Implications:

The GSM of tissue paper directly influences its cost. Higher GSM tissues require more material to produce, which increases the cost. Hence, higher GSM tissues tend to be more expensive than their lower GSM counterparts. By understanding the GSM, manufacturers and consumers can balance cost with the desired functionality and quality.

4. Environmental Impact:

Finally, the GSM of tissue paper can have environmental implications. Higher GSM tissues consume more resources, both in their production and transportation due to their increased weight. Understanding GSM can help both manufacturers and consumers make environmentally conscious decisions.

International Measurement Standards for Tissue Paper

There exist several international standards that guide the production, measurement, and overall quality of tissue paper. Notably, these standards cover aspects such as thickness, strength, absorbency, and other physical properties, with GSM being one key area of focus. The three major organizations that define these standards are the International Organization for Standardization (ISO), the American Society for Testing and Materials (ASTM), and the Technical Association of the Pulp and Paper Industry (TAPPI).

1. ISO Standards:

ISO has developed various standards related to the production and testing of tissue paper. For example, ISO 12625-6:2011 outlines procedures for determining the grammage (GSM) of tissue paper, while ISO 12625-3:2014 covers the determination of thickness, bulking thickness, and apparent bulk density and bulk.

2. ASTM Standards:

ASTM has several standards related to tissue paper. For instance, ASTM D646-13(2018) provides a test method for gram.

Related Topics

– Bamboo Pulp or Virgin Wood Pulp: Which One is More Suitable for Tissue Paper Production?

– A Comparison of Virgin Wood Pulp and Bamboo Pulp for Tissue Paper Properties and Performance

– The Advantages and Disadvantages of Using Virgin Wood Pulp or Bamboo Pulp for Tissue Paper Products

– How Virgin Wood Pulp and Bamboo Pulp Affect the Environmental Impact and Cost of Tissue Paper Production

– Virgin Wood Pulp vs Bamboo Pulp: A Critical Analysis of Their Differences and Similarities for Tissue Paper Applications